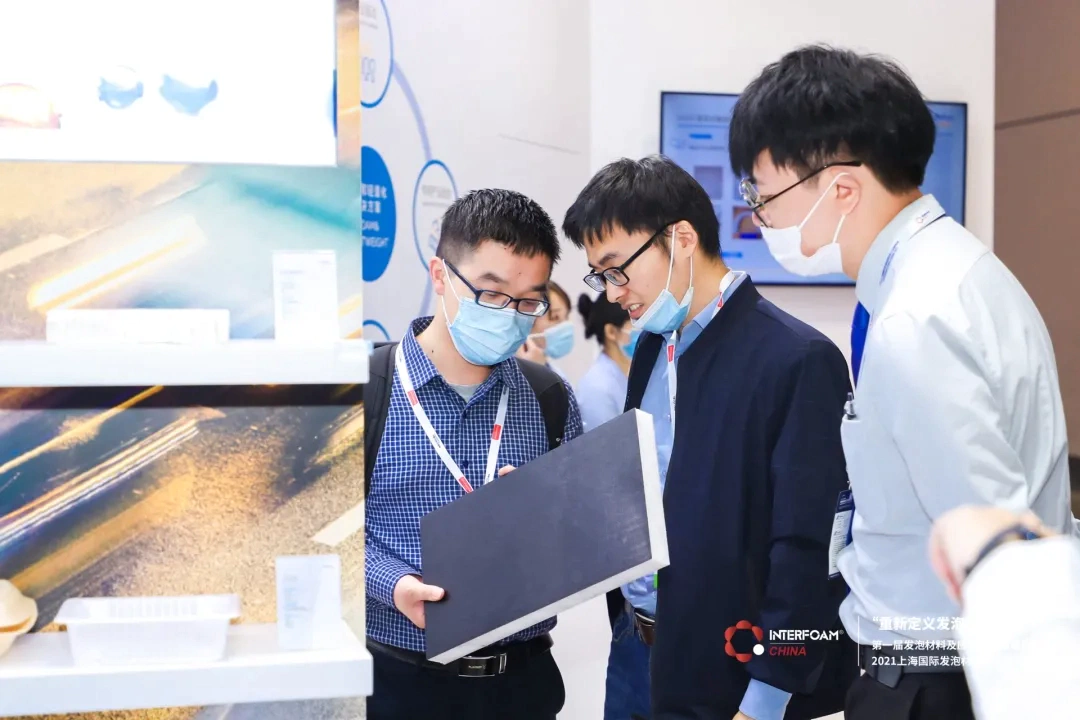

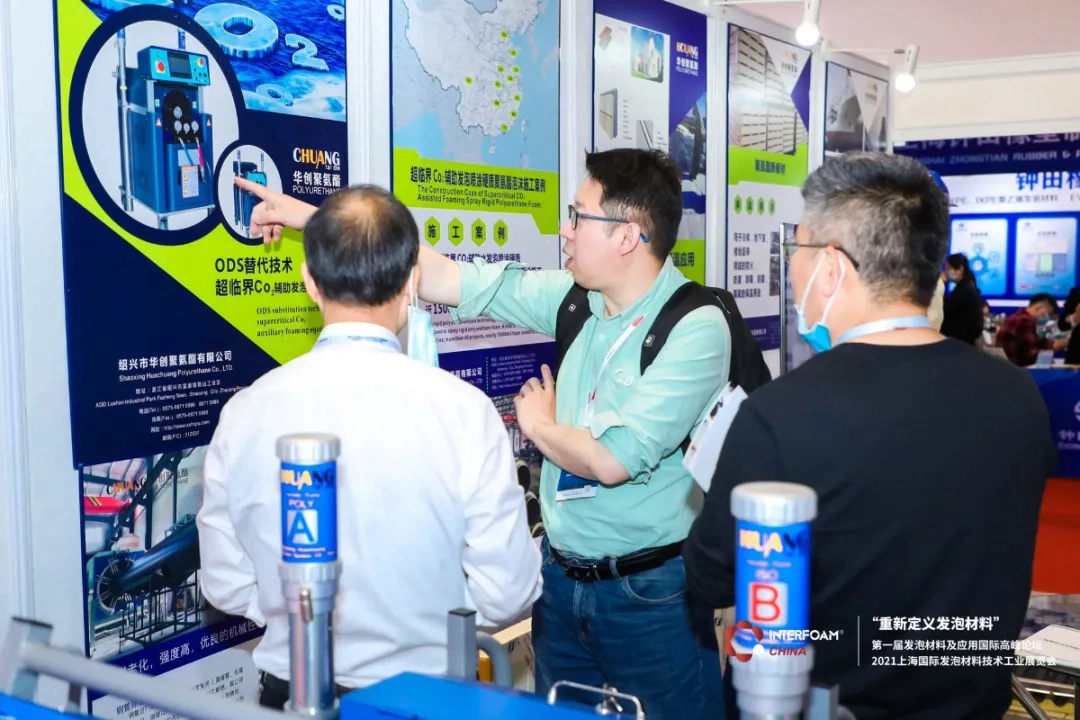

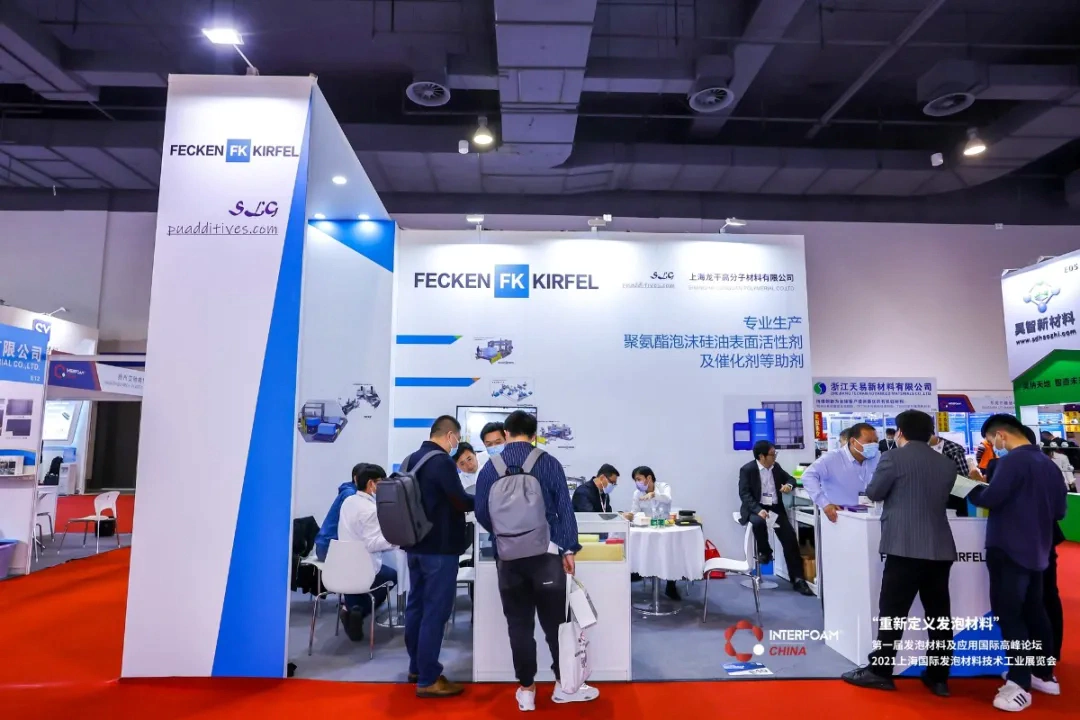

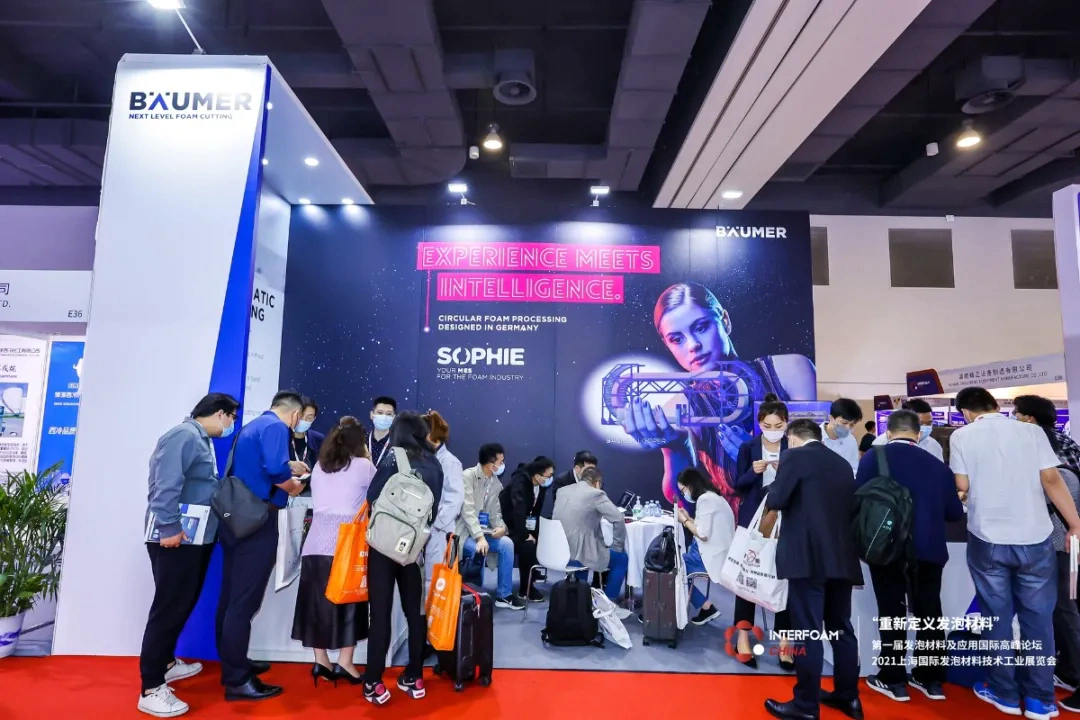

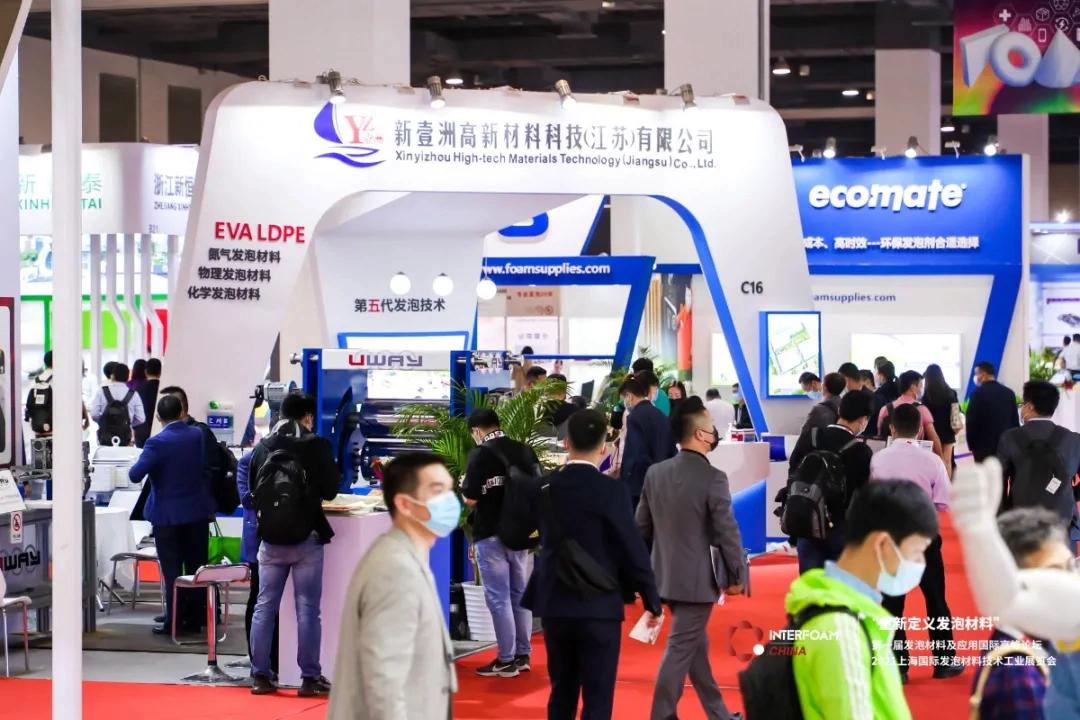

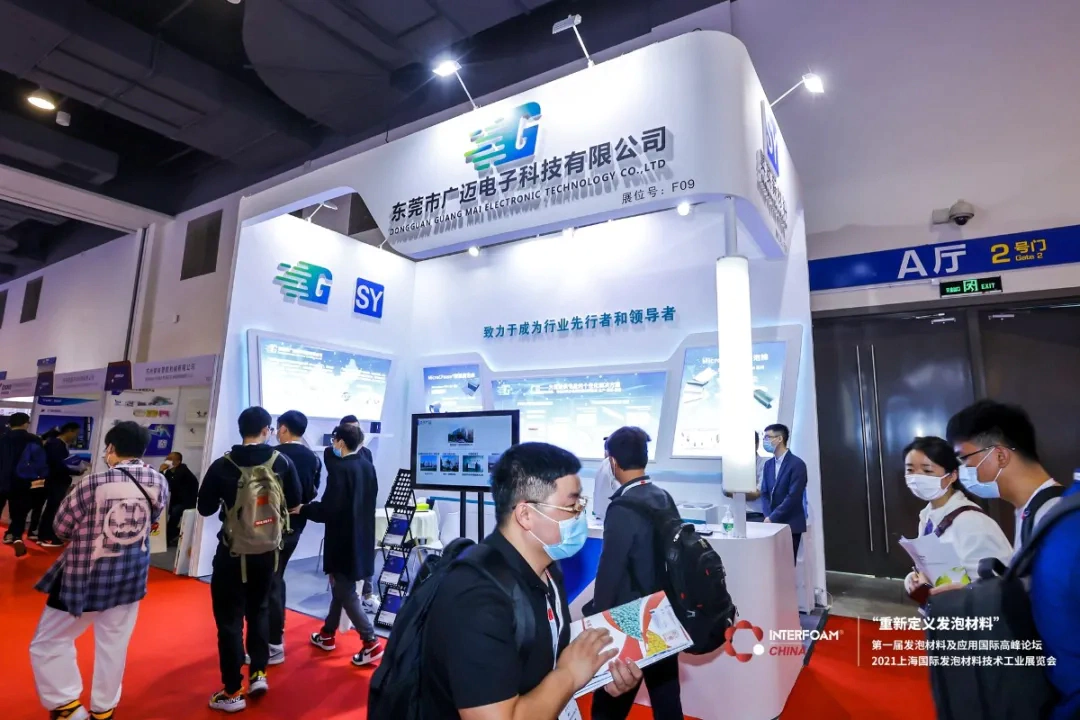

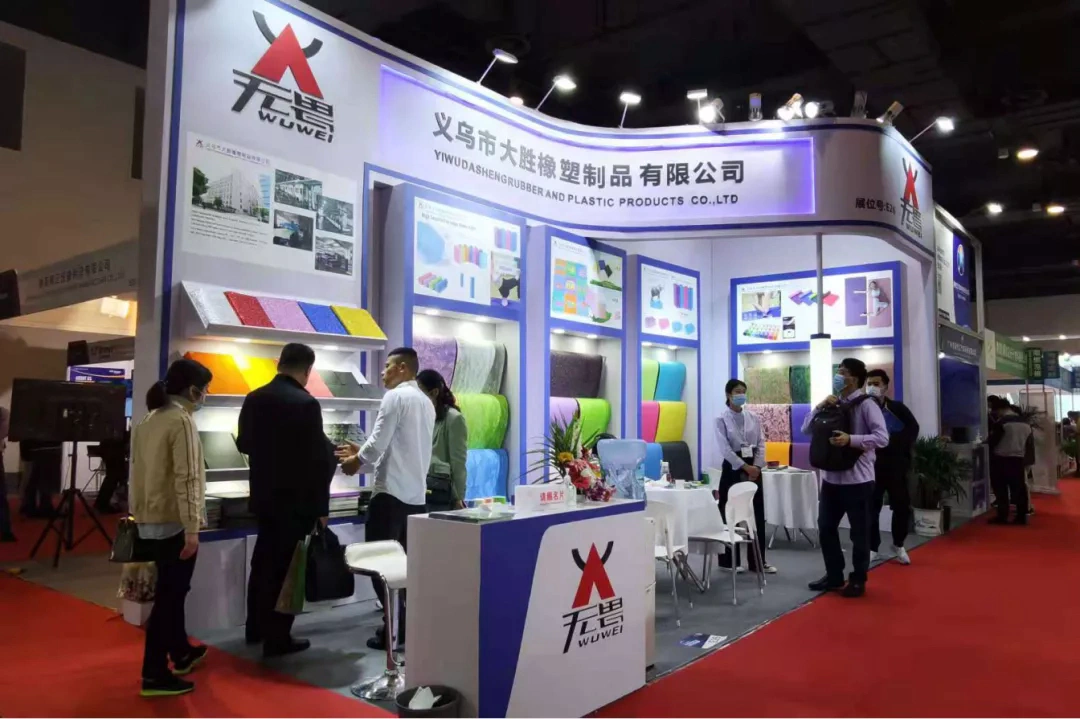

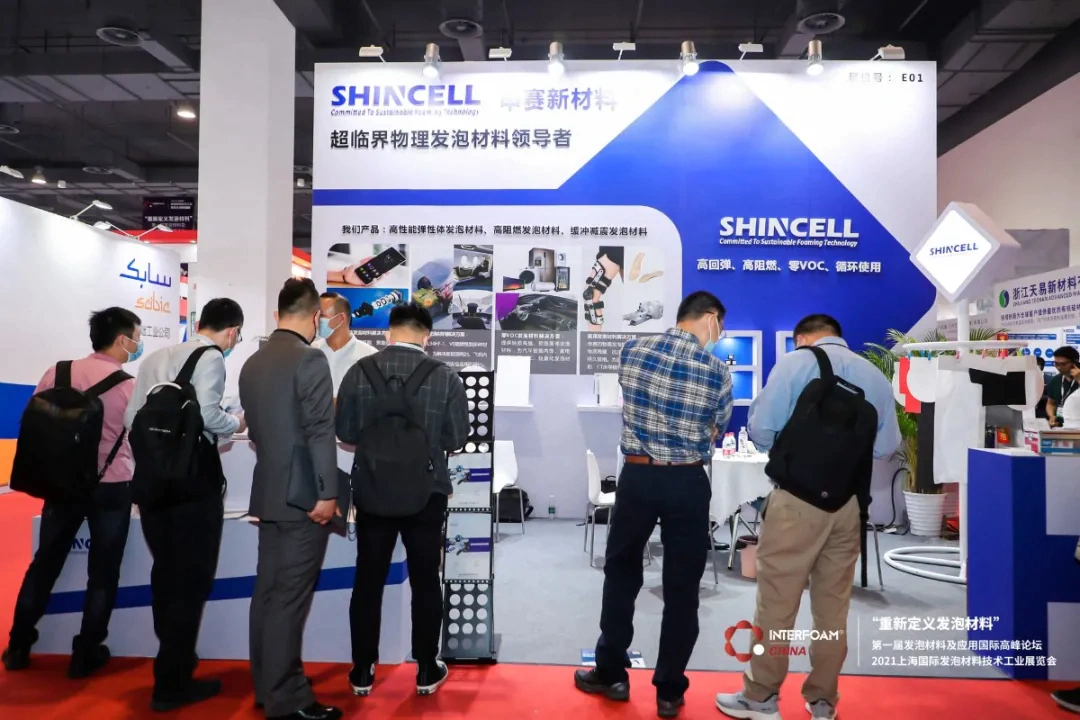

Interfoam China is a professional exhibition for the whole foam industry chain, and is an international event that cannot be missed by the professionals from foam industry all around the world. Interfoam China focuses on the displays of the latest foam products and equipment, new technologies, new trends, new applications and so on, and spares no efforts to build a professional platform integrating trade, brand display as well as academic exchange for both upstream and downstream of the foam industry and its application enterprises, enabling the sustainable development of the industry!

“Carbon Emission Reduction”

Under the strategic framework of “carbon peak” and “carbon neutrality”, we will actively tackle challenges and grasp opportunities to attach more importance to sustainable principles of green, efficient, and harmless development of foaming technologies and applications.

“Technological Innovation”

Under the strategic framework of “carbon peak” and “carbon neutrality”, we will actively tackle challenges and grasp opportunities to attach more importance to sustainable principles of green, efficient, and harmless development of foaming technologies and applications.

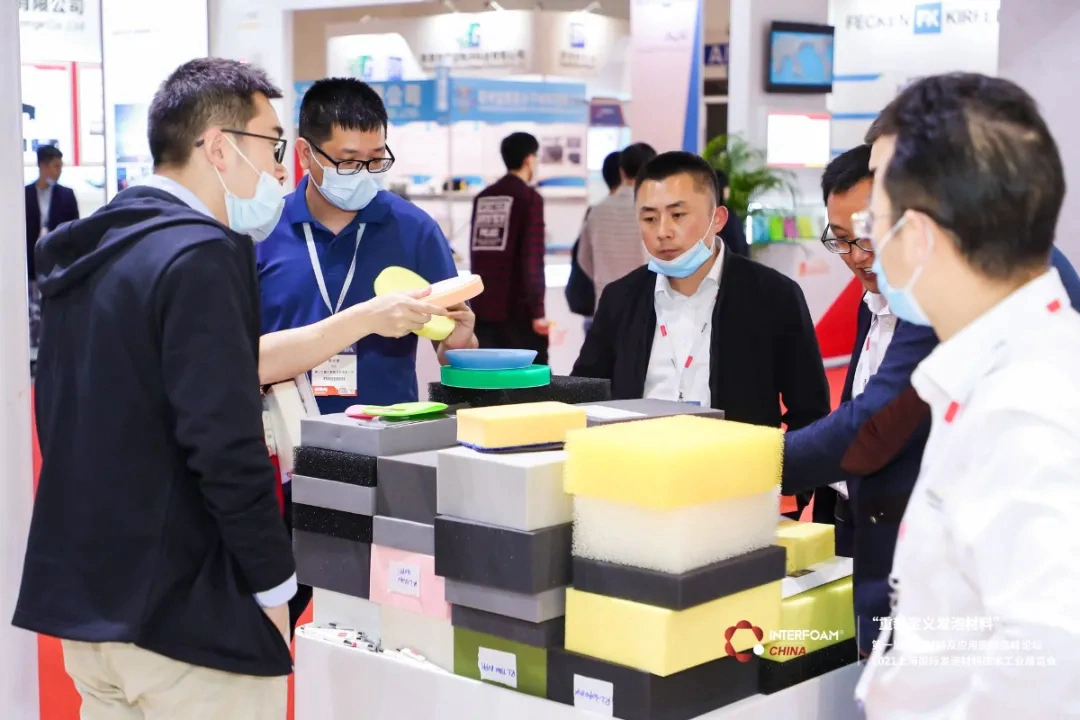

“New Application”

Focus on innovative solutions to the application of foams in vertical fields. Driven by technical innovation and oriented by market demands, we will leverage new technologies, new products, and new plans to create more value for various specific application areas. We will also promote continual innovation to explore infinite possibilities of foam applications.

“High-quality Development”

The “Dual Circulation” pattern requires China’s foam industry to change its structure, accelerate independent innovation and international cooperation, and provides great opportunities for global enterprises to further explore Chinese market. It is firmly believed that foams will meet people’s expectation for a better life, and will form a reliable path towards higher-quality development.

THE BOOMING FOAMS MARKET IN ASIA

Polymer foams is a new force among new materials. Through different foaming process, the polymer is endowed with new excellent properties. Polymer foams play a key role in different vertical applications due to their unique properties such as lightweight, shock absorption, noise reduction, heat insulation and filtration.

"Redefine Foams" The 3rd Foams and Applications International Forum

Based on the theme of last forum—"Redefine Foams", this forum will, from the dimensions of sustainable development, academic research, technical innovation and new applications, discuss the innovation and development of foams and their vertical applications. We will create a positive exchange platform for enterprises, universities, and research institutes, which will cover about 30 topics and be held on-line and off-line simultaneously.

News

Cooperating Partners

Please browse vertically for better experience.